Advancing the Future of Energy

We have a demonstrated track record of reducing emissions in our operations and producing low-carbon fuels for future generations. In fact, yd7610 is on track to achieve 63% global refining GHG emissions reduction/offset target by 2025. We plan to further reduce and offset 100% of our global refining Scope 1 and 2 GHG emissions by 2035 through board-approved projects and carbon capture and storage projects under development.

As part of our strategy to be the safest, most reliable and best operator in the business, we will continue our efforts to:

- Focus on safety, reliability and operations excellence to consistently deliver essential transportation fuels and petrochemical feedstocks;

- Strive to reduce emissions, increase efficiency and invest in opportunities that improve our environmental stewardship;

- Lead the industry in low-carbon renewable fuels, regularly evaluating opportunities to expand production; and

- Execute a long-term strategy that addresses shifting consumer needs under a changing policy and technology landscape.

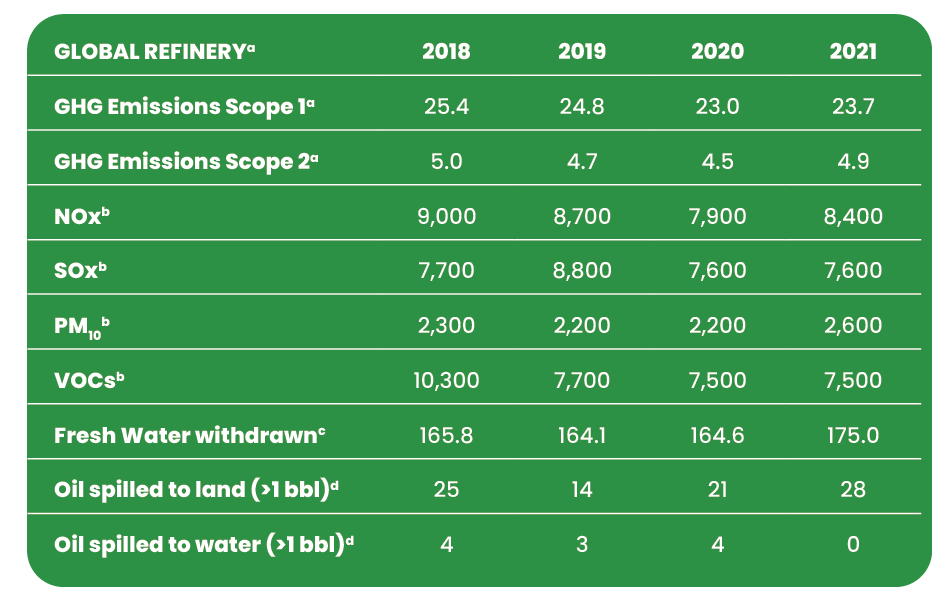

Environmental Metrics

a Million metric tons CO2e. Independently verified Scope 1 is defined as the direct GHG emissions from our 15 refineries. Scope 2 (market-based) is the indirect GHG emissions from purchased electricity and purchased steam used by our 15 refineries. For more information, see note EM-RM-110a.1 regarding GHG emissions on page 109 of the ESG Report.

b Metric Tons.

c Million m3.

d Count of oil spill events to land or water of more than one barrel.

Environmental Management System

We have well-developed management structures central to decision-making and risk management, including three programs that oversee our environmental management:

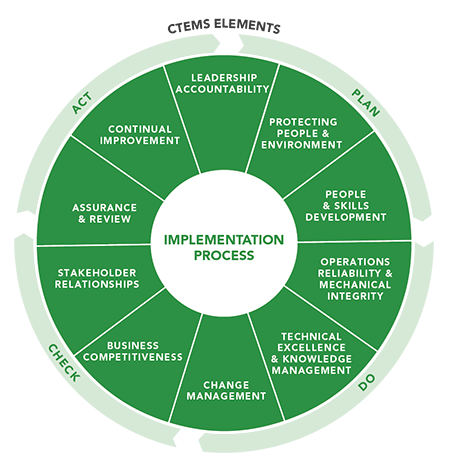

1. Commitment to Excellence Management System (CTEMS): is a proprietary systematic approach to planning, executing, checking, and acting to improve everyday work activities at many of our refineries and plants. CTEMS has 10 elements: leadership accountability, protecting people and the environment, people and skills development, operations reliability and mechanical integrity, technical excellence and knowledge management, change management, business competitiveness, stakeholder relationships, assurance and review, and continual improvement. Risks related to regulatory issues and physical threats to our refineries and plants are among those assessed as we implement CTEMS.

2. Environmental Excellence and Risk Assessment (EERA): elevates the environmental audit and compliance functions to an environmental excellence vision. Its main goal is to assess the design and effectiveness of environmental performance regarding specific excellence objectives, and to facilitate continuous improvement across the company. EERA defines more than 100 expectations and involves a proprietary five-step process using due diligence on data and field assessments reviewed by a combination of external and internal subject matter experts.

3. Fuels Regulatory Assurance Program: provides operational safeguards, software, training, and protocols for uniformity across our refineries and plants to reinforce our compliance with applicable fuels regulations. Building on the success of this system, we are developing a proprietary Low-Carbon Assurance Program designed to provide tools and oversight to assure compliance with the increasingly complex array of low-carbon fuels programs.

What Fuels Us We care about the environment, our employees and the communities where we work and live.

Wastewater Management

Recycling Process